Tiny CNC Milling Copper! YouTube

Sep 21, 2017· Copper is notoriously tough to machine due to it''s malleability, and I''m also faced with a challenging piece to fixture.... Please consider supporting this c...

WhatsApp)

WhatsApp)

Sep 21, 2017· Copper is notoriously tough to machine due to it''s malleability, and I''m also faced with a challenging piece to fixture.... Please consider supporting this c...

Jun 04, 2012· This is a hobby project I have been pursuing for a few years. After having to endure most DIY circuit fabrication methods (marking pen or Kodak PhotoResist and ferric chloride etch, pointtopoint wiring, wirewrapping, insulation displacement, vector board, air wires, XYZ mill etching, cut copper tape, etc) I happened upon a possible quick and ~lowcost solution that appears to beat all ...

Tools for Mechanically Milling and Engraving Printed Circuit Boards (PCBs) ... The plunge style tip geometry insures reliable copper removal at all isolation widths. Both coated and uncoated bits are available from stock. Taperedstub Trace Isolation Tools.

Jan 04, 2018· But before we do that, we need to make sure all necessary precautions have been taken to maximise the mill''s chances of reproducing the circuit. ... To clear off stray copper filings, give the ...

Mar 29, 2017· Copper is one of the top seven metals known since the ancient time. Actually, humankind knows over 170 coppercontaining minerals. Copper melts at 1,0830C. Copper .

How to mill a through hole PCB ... I will include a sample GERBER file for you to use in this project so you can get started milling right away. 3. Copper Clad Board: You will need some copper clad board like FR1, ... I run the .2mm 90 degree universal cutter from Midwest Circuit Tech in my machines. I use that tool at 40k RPM and 45IPM.

Oct 13, 2016· Guide to PCB Issues Printed circuit boards (PCB) are essential components of many electrical devices today, connecting different components to one another through a complex array of circuits. These boards consist of several layers of copper traces to make the connections, as well as plastics and other materials to protect those connections from ...

Mar 12, 2018· Milling process will take no more than 30 minutes however it depends on the thickness of the bit and the size of the PCB and the number components and their alignment it would carry. PCB milling is the method which involves removing the unwanted copper from the board to create paths, and signal traces according to the layout design.

Carbide Copper is CAM software to let you mill PCBs with your CNC machine. Launch Carbide Copper. Carbide Copper is the fastest way to make sameday circuit boards in your own office or shop. Save Time With Carbide Copper and your CNC machine, you''ll be .

This little milling machine is great for quickly making prototypes of PCBs and parts. In this guide we''ll take a look at the process of milling doublesided PCBs. In this project, we''ll make a breadboard adapter for the Adafruit Circuit Playground.

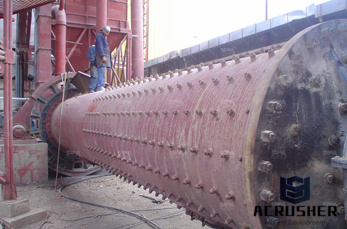

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Apr 22, 2011· PCB Milling Tutorial. 26 Comments ... a set of videos and a PDF guide to milling printed circuit ... boards a reference hole is drilled in the copper clad board to accept a post on the mill table. ...

Printed Circuit Board Quality: Copper Wrap NASA WORKMANSHIP STANDARDS PROGRAM OFFICE OF SAFETY AND MISSION ASSURANCE 1 ... This causes intermittent open circuit failures as the board "flexes" with ... • The arrows in the images point to the crack tips. Cracks appear to be caused

Copper/Molybdenum Ore. The figure above is a simplified flow sheet showing the basic steps involved in a copper mill producing the byproduct molybdenum. The crushed copper ore (containing, for example, % Cu and % Mo) is fed to the grinding circuit where water is added and the ore is .

Google Images. The most comprehensive image search on the web.

A paper circuit is a lowvoltage electronic circuit that is created on paper or cardboard using conductive copper tape, LEDs and a power source such as a coincell battery. Creating paper circuits is a good way to teach the basics of electricity and how circuits function.

Feb 16, 2010· Making your own printed circuit board can be a truly satisfying process, tying together electronics and the handmade craft of etching. It''s the most accurate way to build a circuit short of ...

Buy End Mill Sets, Tungsten Steel CNC Router Burrs End Milling Engraving Bits Drilling Hole Tool For PCB Circuit Board, Plastic, Fiber, Wood, Copper ~ Set of 12: Ball Nose FREE DELIVERY possible on eligible purchases

Make Your Own PCBs on an Inexpensive Desktop CNC Mill: Traditionally, there are two ways of hobbyists making custom PCBs: 1. Using toner transfer and chemical etchant can be tricky to get the right materials, and the chemicals are nasty and messy 2. Paying a service like BatchPCB or OshPark .

Mar 05, 2013· The three main methods of DIY PCB is etching, milling and using a PCB prototype manufacturer. Here is an overview of the three methods. ... DIY PCB – How To Create Your Own Printed Circuit Boards. March 5, ... A CNC mill is a machine that mills off the unwanted copper of your board. When I went to the University of Oslo we had access to a CNC ...

Generate GCode from Eagle PCB layouts (or other programs that export Gerber RS247X signal files and Excellon drill files) for milling on your CNC machine. For our new Carbide Copper PCB software, click here For our Carbide Create 2D CAD/CAM, click here

Printed circuit board milling (also: isolation milling) is the process of removing areas of copper from a sheet of printed circuit board material to recreate the pads, signal traces and structures according to patterns from a digital circuit board plan known as a layout file.

Sometimes you might need to use a 1/64" flat end mill. Less commonly, a 1/16" or 1/8" flat end mill can be used if you need to remove large sections of copper. Typically, to mill small features, it''s best to use a PCB engraving bit instead of a 1/100" flat end mill because the engraving bits have a smaller cutting diameter and are more robust.

Characterization of Printed Circuit Boards for Metal and Energy Recovery after Milling and Mechanical Separation ... cadmium, lead, copper and zinc was observed in sediment samples from a river as a result of metal recovery being carried out using inappropriate techniques, such .

WhatsApp)

WhatsApp)