2000 mesh ball mill YouTube

Feb 18, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Feb 18, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Ball Mill Producing Microns Of Limestone In India. Ball mill producing microns of limestone in india 5 microns limestone powder grinding plant in IndiaZenith Group ball mill producing microns of limestone in indiaCement Industry In India ScribdWelcome to The Cement Grinding Office a new concept to support engineers and technicians working every day with a ball millLimestone Crushers produce ...

GRINDING MILLS Ballmill. Type T Tube Ball Mill can grind materials to a fineness of minus 200 mesh, and is used as a secondary grinding mill after the Type C or Type G Ball Mill. Type T Ball Mills are to produce a finished product from relatively fine feed in an open or closed circuit.

Conical Type VS Compartment Type Ball Mills. The Hardinge Conical Mill—because of its conical shape—offsets one of the serious disadvantages found in the cylindrical, compartment type mill, i. e., unproportionate speeds for the different size balls.

jaw crusher . It can be used to crush material, whose compression strength is not more than 320Mpa. This jaw crusher is mainly used in various industries, such as mining, smelting, road and railway construction, water conservation and chemical industry etc. PE Series is used in primary crushing, while PEX series is used in secondary crushing and fine crushing.

Conical Ball Mill En Venta artdepierre. Conical Ball Mill En Venta . conical ball mill to produce 600mesh teach. Hardinge Conical Ball Mills are used to .

In view of the prominence which the conical mill has attained in the finecrushing field within the few years since its introduction, the following comparison with its more mature forerunner, the Chilean mill, based on extensive tests, is submitted in the interest of the milling profession. Soon after designing the concentrating plant, the conical Ball mill made its appearance in the milling ...

Sep 13, 2010· There are many different types of grinding mills (Table 1). Some devices, such as ball mills, are more suitable for coarse materials. These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes. Attrition mills are more appropriate for "midrange" size particles.

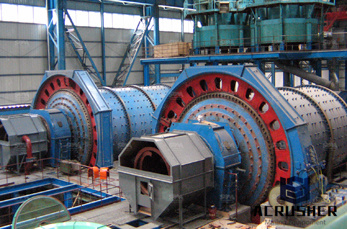

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

grinding mill for line to produce mesh mesh limestone mill voetzorgvrijenburg. Grinding Mill For Limestone To Produce 35 Mesh FTM limestone grinding mill is the star product of Henan Fote Heavy Machinery Co,ltdand it is a grinding . ultra fine grinding mills for 1000 mesh oalebakkershoes. ... Ball Mill 05 Micron Micro ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

9. Work on ball mill, filter press, pug mill. 10. Make the crushing of potash/silica lumps and grinding in conical ball mill. 11. Select the required mesh size during grinding of material in conical ball mill. 12. Describe the optimal grinding of ball mill. 13. Handle the various machines with safety. 14. Do the proper cleaning of machine and ...

Ball Mill With Product Size 0 037 Mesh Ball crushing mill China ball mill will crush the material and then crushed china crusher machine is a crushing machinery crushing machinery was used in the discharge size of more than three millimeters of the total volume accounted for more than 50.

The Conical Mill is now being used in all parts of the World, having substituted these latter types of ma chines in the grinding of ores and other materials. Hardinge Conical Ball Mills are used to do the work of any combination of the above machines and will pro duce the desired results, depending upon the size and type of mill used.

Pharmaceutical Sieve Mill | Conical Milling. A sieve mill provides the perfect solution to material size reduction in pharmaceutical manufacturing. It is used for reducing the size of dry material in production, delumping material postdrying, sizing wet material postgranulation (increasing surface area for quicker drying) and deagglomeration of clumped material, as well as for various other ...

Conical Milling Machines To 80 Mesh sand washing machine. brazil 40 80 mesh milling equipment price Quadro Solids Division is a leader in technological engineering and manufacturing of products such as conical mills machine. Conical Mills (UnderDriven) final particle sizes and throughputs. Conical mills are typically suitable for size ...

Metallurgical ContentBall Mill Grinding P80 SizeCylindrical Ball MillsConical Ball MillsRod MillsBall Mill and Rod Mills DrivesGrinding Media Ball Mill LinersCylindrical VS Conical Ball MillsBall Mill Animation The ore from the crushing section is delivered to the fine ore bin placed at the head of the grinding section, from which it is fed, together with water, to one or more grinding units ...

The solid concentration during wet grinding was 70 vol.%. The grinding procedure of this conical ball mill has been described in detail in the literature . To determine the weight fraction (wt.%) in the feed size interval and size distribution of ground particles, the ground sample was sieved using 1,,,,, and mm sieves.

A ball mill, a type of crusher, is a cylindrical device used to grind chemicals or mix mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium, ideally non sparking milling media like lead balls.

Ball mill shell liners are used to protect the inner shell of cylinder from being impacted and worn directly by material and grindball. At the same time we can use different forms of the shell liners ...

Dec 16, 2014· FZ Series Fritz/Cone Mill Working Principle: The material to be processed enters into the feed inlet of grinding and granulating machine, which drops into the conical sieve chamber.

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Table of ContentsBall Mill LiningSpeed of Ball MillsCompare a Hardinge Ball Mill to Chilean Pan MillPerformance Comparison: Conical Ball Mills VS Cylindrical Ball Mills Nearly every mining and metallurgical engineer will recall his early experience and method of producing step or stage reduction in preparing oresamples for assay, in which he employed idea, step or stagereduction simply ...

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

WhatsApp)

WhatsApp)