Synthesis of graphene nanoflakes by grinding natural ...

Synthesis of graphene nanoflakes by grinding natural graphite together with NaCl in a planetary ball mill

WhatsApp)

WhatsApp)

Synthesis of graphene nanoflakes by grinding natural graphite together with NaCl in a planetary ball mill

ball milling in nanotechnology ball milling in nanotechnology in,, metal acetate is and the organic ligand are ground and mixed with a ball mill View PDF Version Live Chat; ball milling process of nanotechnology Ball Milling Diagram Nanopowder Synthesis sdklubcz. Read the rest > Get More

SYNTHESIS OF ZIRCONIA NANOPOWDER USING PLANETARY BALL MILLING METHOD AND ITS POLYMERIC NANOCOMPOSITE PROJECT REPORT Submitted by DESHPANDE SIDDHARTH P. () SINGARE SUMIT S. () SABE POOJA S. () Under the guidance of Dr. R. K. Goyal ABSTRACT The project deals with preparation of nano zirconia powder using planetary ball ...

Mechanical alloying is a "brute force" method of affecting alloying and chemical reactions. The mixture of reactant powders and several balls are placed in the milling jar of a highenergy ball mill,... Prof. Laszlo Takacs Material Matters 2007,, 21.

Before using metal nanopowder, if there is some gas inside bag, with a small needle to puncture a small hole at corner of the packaging bag, then softly adding pressure on the bag to release the gas. If the bag temperature (heating up ) goes up, you can stop a moment .

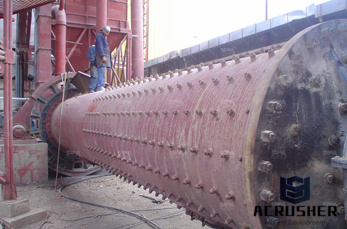

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Oct 02, 2017· Looking for a solution to produce a high variety of confectionery masses?

This paper details with synthesis of Molybdenum Disulfide (MoS2) nanopowder by using planetary ball mill. The ball milling was carried out at 250 rpm in dry condition for 0 to 20 h. Scanning electron microscope (SEM) clearly indicates that size of MoS2 decreases with increasing ball milling time. However, at higher milling time formation of ...

Dec 15, 2012· Nano Ball Milling 1. BALL MILLING METHOD By Aravind N. B 2. Nano materials can be defined as those materials which have structured components with size less than 100nm at least in one dimension. Nanotechnology is an advanced technology, which deals with the synthesis of nanoparticles, processing of the nano materials and their applications.

For all nanocrystalline materials prepared by highenergy ball milling synthesis route, surface and interface contamination is a major concern. In particular, mechanical attributed contamination by the milling tools (Fe or WC) as well as ambient gas (trace impurities such as O 2, N 2 in rare gases) can be problems for highenergy ball milling ...

Nanoparticle are particles between 1 and 100 nanometres (nm) in size with a surrounding interfacial layer. The interfacial layer is an integral part of nanoscale matter, fundamentally affecting all of its properties. The interfacial layer typically consists of ions, inorganic and organic molecules. Organic molecules coating inorganic nanoparticles are known as stabilizers, capping and surface ...

Mechanochemical synthesis of two or more different precursors is a simple method to prepare metallic alloys, polymer and ceramic composite materials. This mechanical reaction based synthesis also has been employed to produce hydroxyapatite (HA) powder for bone implant application. In this present study, we employed mechanochemical method to synthesize hydroxyapatite nanopowder from dry .

Dec 22, 2016· Prototype high energy eliptical ball mill for nanopowder metallurgy ... Retsch Cross Beater Mill SK 100 ... 5:50. 3D Ball Mill pulverizes and mixes with highspeed 3D motion #DigInfo ...

Mechanical alloying is a "brute force" method of affecting alloying and chemical reactions. The mixture of reactant powders and several balls are placed in the milling jar of a highenergy ball mill,... Prof. Laszlo Takacs Material Matters 2007,, 21.

During the last decade numerous protocols have been published using the method of ball milling for synthesis all over the field of organic chemistry. However, compared to other methods leaving their marks on the road to sustainable synthesis ( microwave, ultrasound, ionic liquids) chemistry in ball .

This paper details with synthesis of Molybdenum Disulphide (MoS2) nanopowder by using planetary ball mill. The ball milling was carried out at 250 rpm in dry condition for 0 to 20 h.

Why I cannot get Alumina particle in nanosize scale using ball milling method? Several milling sessions using 5mm, 1mm and mm grinding ball were carried out to produce alumina nanoparticle ...

Jul 03, 2013· Synthesis of nanoparticles physical,chemical and biological 1. SYNTHESIS OF NANOPARTICLES 2. Materials having unique properties arising from their nanoscale dimensions Nanomaterials with fast ion transport are related also to nanoionics and nanoelectronics Nanoscale materials can also be used for bulk applications Nanomaterials are sometimes used in solar cells .

Ball Milling An efficient and ecologically friendly synthetic approach ‐‐‐ Jackie Ding . Ball milling – solvent free approach Application in organic synthesis Conclusion Content 2 .

Ball Milling Diagram Nanopowder Synthesis . ball milling diagram nanopowder synthesis ball milling diagram nanopowder synthesisBall mill A ball mill is a type of grinder used to grind and blend materials for . Ball Mill RETSCH powerful grinding and . A ball mill can grind and homogenize small sample volumes down to the nano range.

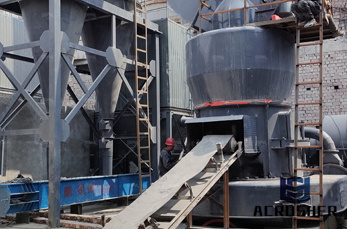

the Synthesis of Nanomaterials and Nanocomposites . the inner walls of the mill because of the centrifugal force dominating over centripetal force. For large scale production tumbler mills are more economical when compared to the other high energy [26]. While a number of ball mills ingenious milling devices were developed early in the cen

Ball Milling method for synthesis of nanomaterials. There are different methods for synthesis of nanomaterials. Today I will discuss the ball milling method. Steps in ball milling method; 1. As the name suggests, the ball milling method consists of balls and a mill chamber. . This powder will be made into nanosize using the ball milling .

Ball Milling Diagram Nanopowder Synthesis 5826 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry.

Dec 18, 2018· A mechanical ball milling method for ultrafast synthesis of a nickelbased metal organic framework (NiMOF) has been proposed. The NiMOF was successfully synthesized in merely one minute without any solvent, additives, or preliminary preparation.

WhatsApp)

WhatsApp)