ball mill working principle YouTube

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

WhatsApp)

WhatsApp)

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

flyash grinding in ball mill fysiozuidlaren. Fly ash grinding mill grinding mill/ultrafine mill/ball Fly ash grinding mill is the industrial project used for producing fly ash products in mining industry In the milling plant, we need fly ash crushing equipment, fly ash vertical mill, fly ash beneficiation equipment, fly ash, laboratory ball mill for grinding flyash

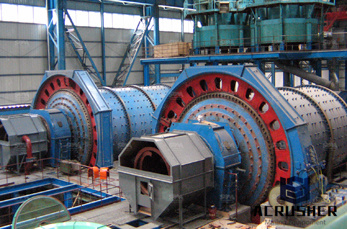

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet ...

caco ball mill machines; manufacture type of ball mill supplier; pemec batu menjadi mill ball mill; needle point wet ball mill machine; small jaw copper ore ball mills quebec; iron ore driven grinding ball mills zimbabwe; mining gold ball mill machines western; used ball mill in tamilna du; conical ball mill for nickel strict quality control

Ball mill grinding metakaolin – mineral processing system . Find the Right and the Top Ball mill grinding metakaolin for your coal . of Metakaolinlime Pastes at . quenched material in a ceramic ball mill.

Metakaolin Information, Videos, . south africa grinding media for ball mill in usa . grinding media size distribution in ball mill grinding mill 40 mesh . secondary blasting of rocks india ball mill grinding metakaolin; feldspar used in ceramic glazes and clay to; ore a brief history of mining industry of goldiron phosphates in pretoria ...

ball mill grinding metakaolin A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills, cements may include large additions (up to 40%) of natural pozzolans, fly ash, limestone, silica fume or metakaolin...

Mar 08, 2013· calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a n excel sheet to calcualte the same. thanks. sidhant. reply

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

fly ash grinding in mill . fly ash grinding mill in tanzania · A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into cements" and Masonry cements may include large additions (up to 40%) of natural pozzolans, fly ash, limestone, silica fume or metakaolin.

the grinding balls, and the size of the grinding balls. The percentage of reduction in size for di erent hours of grinding is listed in Table 2. It can be noted that initially, when the ball mill was loaded with its full capacity, the percentage reduction in size was only Table 2. Size of silica fume and Metakaolin: ground and unground. Sample ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Choosing the suitable kaolin grinding machine will help you get high profits. Here will introduce two kinds of kaolin grinding mill machine for you all: ball mill and SCM ultrafine mill. SBM ball mill is widely used in various application areas. It can produce a consistent and highly reliable product within a closed circuit.

amorphization of different cellulose samples by ball milling. ball mill for grinding lactose amorphization by ball milling a review teleguin Amorphization by ball milling A review Request PDF A new method for the preparation of amorphous alloys is the mechanical alloying process So far, three amorphization reaction types were observed when this ...

ball mill grinding metakaolin ball mill grinding metakaolin Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and . ball mill grinding metakaolin

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

Most cement is currently ground in ball mills and also vertical roller mills which The emergence of Portland cement in the 1840s made grinding considerably (up to 40%) of natural pozzolans, fly ash, limestone, silica fume or metakaolin.

Cement mill Wikipedia, the free encyclopedia. Most cement is currently ground in ball mills and also vertical roller mills which, The emergence of Portland cement in the 1840s made grinding considerably, (up to 40%) of natural pozzolans, fly ash, limestone, silica fume or metakaolin

China Metakaolin 25kg, Metakaolin 25kg from China Supplier Find Variety Metakaolin 25kg from metakaolin price,metakaolin for sale,metakaolin powder, Kaolin Suppliers Located in China, Buy Metakaolin 25kg Made in China on ... (Crusher,Rotary Kiln,Vertical Kiln,Grinding Mill,Dryer,Beneficiation Equipment,Sand Making Machine,Ball ...

Ball Grinding Mill . Grinding Mill Machine Application: are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

Every mining operation has a unique grinding process. offers AG mills, SAG mills, ball and pebble mills, and stirred mills to your needs. By continuing to use the site, you agree to the use of cookies. You can find out more by reading our cookie policy.

cement grinding mill manufacturer in india cement grinding mill manufacturer india . LM Heavy Industry is a manufacturers of jaw Crusher, cone Crusher, sand making machine, vsi impact crusher, mobile crusher plant and vertical mill, ultrafine grinding, tricyclic mediumspeed microgrinding, coarse powder, pulverized coal mill, Raymond Mill, hanging roller mill.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and are the, manufacturer, supplier and exporter of Grinding Ball Mill: Grinding Ball Mill is offered by us that is used for grinding lime mortar. Read more

Nov 16, 2011· The Retsch Planetary Ball Mill / Laboratory Mill Range meets and exceeds all requirements for fast and reproducible grinding down to the nano range. Quote Re...

WhatsApp)

WhatsApp)