Roller shells for pellet mills General Dies

We internally produce roller shells made of high quality material, of any dimension and type for all pellet mills on the market.

WhatsApp)

WhatsApp)

We internally produce roller shells made of high quality material, of any dimension and type for all pellet mills on the market.

The Antares roller mill comes in two designs – the fourroller mill MDDR and the eightroller mill MDDT. Roller lengths range from 600 mm to 1500 mm, with two diameters – 250 mm or 300 mm. You can add various options including automatic grinding gap adjustment, roller and bearing temperature monitoring, water cooling and direct suction.

NKE single row cylindrical roller bearings offers unlimited possibilities for your applications. Currently more than 3,000 types of this series are produced in Steyr using a .

Roller mills use rollers instead of hammers to cut, crush, or tear the grain into smaller pieces. Gehl is credited with creating the first hammer mill meant for grinding grain, and you''ll still find used Gehl feed grinders and grinder mixers for sale. Art''s Way, Automatic Equipment Manufacturing, New Holland, and Renn are among other ...

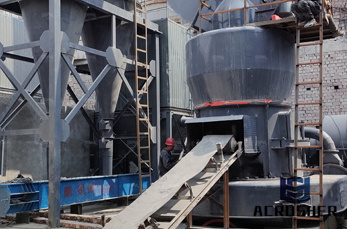

Mar 19, 2017· LOESCHE has been able to sell five large vertical roller mills to the emerging cement market in Algeria. The local building sector in Algeria is one of the drivers of increasing cement demand, which now stands at million tons per year in this NorthAfrican country, and is not being met by the current annual production of around million tons.

Flour Milling Equipment FMFG(Q) Series Roller Mill. Features: rollers distributed horizontally which balance the system internal force. feeding rollers, four rotator speeds and seven flute types to ensure the feeding accuracy.

Loesche has been able to sell five large vertical roller mills to the emerging cement market in Algeria. The local building sector in Algeria is one of the drivers of increasing cement demand, which now stands at million t/a in this NorthAfrican country, and is not being met by the current annual production of around million t.

Algeria: Biskria Ciment has ordered five vertical rollers mills from Loesche. The contract includes two raw cement mills and three clinker mills for the plant at Biskra. With these mills raw cement meal can be ground to a fineness of 12% sieving residue with 90μm at a processing capacity of 500t/hr and the cement clinker to a fineness of 3,400 Blaine.

Pfeiffer vertical roller mill of the type MPS 100 GC for a plant in Bou Saada/Algeria. The MPS mill is designed for the grinding and calcining of 14 t/h of natural gypsum at a residual crystal water content of about 5 % and a product fineness of % residue on scope of supply includes the complete mill with classifier and the ...

The two crushing rollers are driven by a Vbelt drive. The doubleroller mills are executed by us in two versions: In the laboratory version, the machine is equipped with a tamperproof feeding funnel, the base frame with integrated control system and the safetymonitored collecting box.

It is one of our 60 TPD automatic wheat flour mill plants built in Ziti Ouzou, Algeria. The cost of this flour plant is 75,000. Below are the features of this small flour milling solution. Feel free to send us an inquiry if you are interested in this plant and want to know more details. Grain Cleaning System

Such particle sizes can only be obtained in connection with an air classifying step. Spiral jet mills have a static air classifier integrated into the mill housing, whereas fluidised bed opposed jet mills are equipped with a dynamic deflectorwheel classifier. The fineness is set as a function of the classifying wheel speed.

Therefore, our roller mill rolls or flour mill rolls have consistency and reliability. As a result, it improves the efficiency of your flour mill and reduces the downtime of your flour mill. Furthermore, we can supply you the flour mill rolls in smooth (grinded), fluted (grooved) or sandblasted (frosted) condition.

This wheat flour mill project was built in 2012, has been running for 3 years. It is one auto control wheat flour production line.

A good maize flour milling is comprised of a cleaning process, conditioning process, a degermination process, uses roller mills and sifting process. Milling and sifting are the essence of grain processing so a good maize milling machine must have a good sifting processes and roller millers.

MVR vertical roller mill from Gebr. Pfeiffer with patented multiple drive system MultiDrive® for the highest throughput rates and permanent plant availability ... Electric energy consumption of Pfeiffer roller mills is reduced by up to 40% as compared with conventional ball mills. ... CBMI Biskra, Algeria. MVR 6700 C6 cement mill with ...

Cruver Mfg Co Chicago. Wabasha Minn. Wabasha Roller Mills. BIG JO (Flour). Riverside Mills. Antique Advertising Mirror. beautiful woman on front with advertising. wear and tear with age and use.

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is .

2. Maize Mills Milling Section: 1)Roller Mills: China roller mills, Highly automated, hightech, easy to operate. 2)Plansifter: Fullyenclosed new type, easy to dismantle and install screens, flexible screen path, can classify materials into a variety of different characteristics according to customer requirements.

Kompaktors | Roller Presses With a Roller Press (Kompaktor) through compaction or dry granulation granulous bulk material is created from a powder. The Kompaktor is also called roller press, roller compactor or dry granulator. If it is used for crushing, the Kompaktor is also called high pressure roller .

EquipNet is the world''s leading provider of used equipment including used mills and much more. Our exclusive contracts with our clients yield a wide range of used mills from a number of respected OEMs, including Fryma Koruma, , Szegvari, Fritsch, Skoda Machine Tool, and many are constantly receiving a variety of used 2 roll mills, colloid mills, hammer mills, media mills ...

Continental Agra Equipment, Inc. 1400 S. Spencer Rd. Newton, KS 67114 USA Hours of Operation: 85 MF CST Weekends by appointment only

Find Mining Equipment For Sale or Lease including Trucks, Dozers, Loaders, Crushers, Underground, Conveyors, Mills, Drills, and much more.

WhatsApp)

WhatsApp)