ABB to revamp high pressure grinding rolls ...

Sep 24, 2012· Baden, Switzerland, September 24, 2012 – ABB, the leading power and automation technology group, won an order to upgrade Anglo American Platinum''s high pressure grinding rolls .

WhatsApp)

WhatsApp)

Sep 24, 2012· Baden, Switzerland, September 24, 2012 – ABB, the leading power and automation technology group, won an order to upgrade Anglo American Platinum''s high pressure grinding rolls .

Dec 29, 2012· For more mineral processing videos visit my YouTube Channel: Detailed description of the working and theory behi...

Enduron ® high pressure grinding rolls (HPGR) set the benchmark for energy efficient grinding and use dynamic skewing to provide bestinclass wear life for mining applications. Overview With low energy consumption, low maintenance requirements and high availability, Enduron® high pressure grinding rolls are a proven way to improve the ...

HRC™ Mining Magazine award winner 2015! Mining Magazine has recognized ''s HRC™3000 highpressure grinding roll with its annual Minerals Processing award. The awards are given out in 11 categories and the winners are nominated by readers.

The use of high pressure grinding rolls (HPGR) is growing in iron ore processing. Because of the high technology of this kind of crusher, optimum utilization requires a thorough understanding of the effect of parameters on their operation. An important factor for consideration in the operation of ...

focused on this energyefficient grinding technology by utilizing a singleparticle roll mill as well as a 200 mm by 100 mm high pressure grinding rolls at the University of California, Berkeley, USA. They studied the effect of HPGR operating parameters and developed fundamental models to simulate high pressure breakage phenomena.

HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining. The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years. After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores.

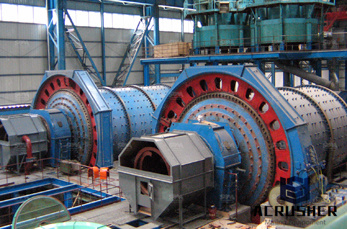

Used in mining applications for the last 30 years, High Pressure Grinding Rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them.

HRC™8 highpressure grinding rolls. HRC™8 takes manufactured sand to the next level by providing a simple yet robust design, a low cost of operation, and improved product shape and gradation.

With industry demand for high pressure grinding rolls (HPGR) on the up, Minerals is arguing that skewing is a vital feature for modern HPGRs to reduce wear, save downstream energy and ensure optimal grinding across the whole feed.

2 DRIVE YSTEM OR HIGH PRESSURE GRINDING ROLL ROLLXTEND™ Application challenges Today''s highly competitive mining industry calls for continuously operating, high throughput equipment, such as the HPGR, to be designed for maximum availability and reliability. A HPGR''s optimum point of operation is widely influenced

Industrial Solutions for the minerals and mining industry The nextgen HPGR More highend – more economical – more efficient – more reliable . thyssenkrupp Industrial Solutions | HPGR High Pressure Grinding Roll Benefit from our nextgen HPGR Whatever your business – copper or gold megaconcentrators, pebble crushing, lumpy or ...

High capacity High Pressure Grinding Rolls for all your use cases. During its relatively short history in minerals processing, HPGR technology has undergone significant development in machine roll wear surfaces and control philosophy.

High Pressure Grinding Rolls (HPGR) were introduced as a new grinding technology in 1984. Since then, they have been successfully installed in a large number of plants throughout the world, mainly for cement and limestone. More recently, HPGRs have also been applied in mineral processing plants, largely in iron ore and diamond treatment.

Highpressure grinding roll Page 1 of 1 sells KHD HPGR to Goldrock Mines Minerals has sold a KHD high pressure grinding roll (HPGR) to Goldrock Mines for installation in...

PDF | The issues concerning operating parameters of HPGR were presented in the article. The HighPressure Grinding Rolls technology is currently the most efficient method of crushing in hard ore ...

Home › Mining › Metallurgy and ... High Pressure Grinding Rolls (HPGR) is a mature technology that is proven to reduce capital and operating costs in full scale plants when compared to other comminution technologies. SGS comminution experts have developed a simple testing methodology to avoid some of the difficulties associated with using HPGR.

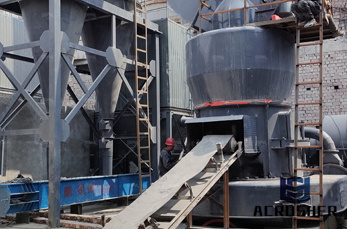

1. Using a highpressure roller mill in the process of the grinding system can increase the production efficiency of the entire system by 20% to 30%. At the same time, the total power consumption of the grinding system can be reduced by 25 to 50% compared with the conventional grinding method. 2.

Mar 12, 2009· At the Peñasquito ore grinding plant in Mexico, which is located in the mining state of Zacatecas,. ABB will supply a medium voltage (MV) variable speed drive system that includes two motors, two transformers, and two MV ACS1000 water cooled converters for the highpressure grinding rolls. The drive systemhas a power capacity of 2 x 2500 kW.

Through historical cooperation with KHD in the manufacture of High Pressure Grinding Rolls (HPGR) CITIC HIC now designs and manufactures a full range of HPGR''s to suit the cement and mineral processing industries. With over 170 units sold CITIC HIC has the experience in supplied world class HPGR''s to the industry.

High Pressure Grinding Rolls (HPGR) HPGRs are modern and efficient comminution machines, which are becoming more and more popular in mineral processing. In addition to the industryleading equipment that TAKRAF already offers to the mining industry, the TAKRAF HPGR is a benchmark in further developed comminution technology

Business; High Pressure Grinding Rolls HPGR Market Revenue 2019: ThyssenKrupp, , Köppern Group, , FL, Chengdu Leejun Industrial, CITIC Heavy Industries, Hefei Cement Research and Design Institute, TAKRAF, Chengdu Dongli Machinery, Sinosteel Anhui Tianyuan, Luoyang Zhongyuan Mining Machine

High pressure grinding rolls, also called roller presses, have been used in the treatment of iron ore, copper (Fig.), gold, diamond and various other ore types for many years. Contrary to conventional crushing rolls, the particles are broken by compression in a packed particle bed, and not by direct nipping of the particles between the two rolls.

Aug 15, 2019· Across the resources sector, mine owners are looking to high pressure grinding rolls (HPGR) to improve the energy efficiency of their greenfield projects. Favoured for decades in cement production, HPGRs are now being used in hard mineral comminution to offset the .

WhatsApp)

WhatsApp)